The Shadowfast super car project

|

|

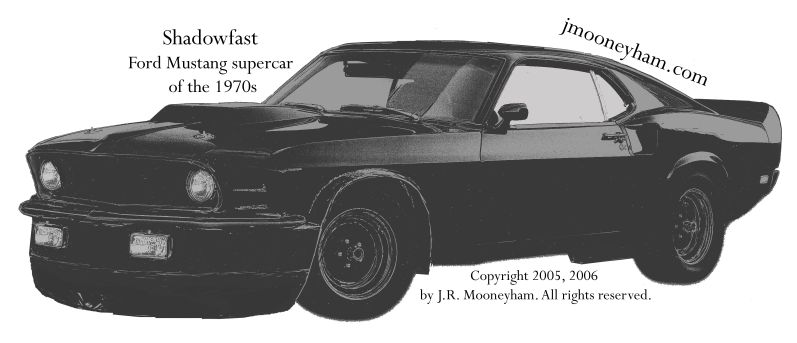

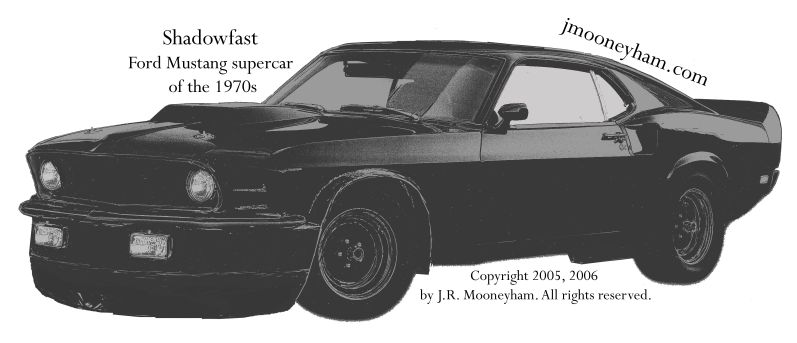

Above my artistic rendition of Shadowfast with his flexible lower air dam installed. This perspective also offers a view of his extended custom rear spoiler and traction bars. I've included signs of wear and tear on the foremost central point of Shadow's flexible dam's lower edge, as such was frequently visible on the car during its treks. The way the flexible dam was stressed the central front angled slightly outwards while the sides slightly drew inwards: I've tried to reproduce this above as best I could (RARE PHOTOS).

|

If you'd prefer to see all of Shadowfast's technical details in ebook form, Dark Horse: The Official Shadowfast Supercar Technical Reference is now available for any Amazon Kindle or Kindle app.

Though I did change the car's name in the stories to Shadowfast from its actual name of Shadowfax, a recent examination of notes from the time shows I considered both names early on. So basically they can be used interchangeably for our purposes here.

Plus, I find that now in my old age I much prefer the name Shadowfast-- since the Peter Jackson films have made the name of Gandalf's steed in the Lord of the Rings much more common knowledge than it was in the seventies.

The actual final specifications of Shadowfast, as best I can recall with the help of incomplete notes and sketches from the time

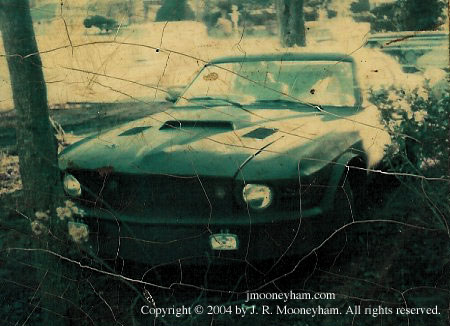

Shadow began as a 1969 Ford Mustang Mach One which had already seen a hard life, according to stories I heard of the previous owner(s), and by the state of affairs in which I found the car at purchase. It sported a black exterior and white interior. 351 cubic inch Windsor motor and FMX 3-speed transmission. No air conditioning, no power brakes, no power windows or locks. It did have power steering. Fake hood scoop. Fake rear brake scoops. Fastback profile. The only spoiler was the small hump built into the trunk lid and rear corner pieces. Drum brakes all around. No anti-sway bar on the rear; just a small one under the front. Limited slip rear-end (not posi-traction like I believe Steve's Boss 351 was). A 20 gallon gas tank I believe (my notes fluctuate on this point, possibly due to me contemplating different tank arrangements). It sported slotted mag wheels. It appeared filthy and ill-treated.

It turned out I'd been amazingly lucky in my choice of vehicle-- at least in regards to upgrading it to a supercar. For it turned out to be above average in several critical performance elements straight from the factory, such as suspension and easy performance boost options. Part of my luck was Ford had decked out some close cousins with the best gear they could (1969 and 1970 Boss 302s and Boss 429s). Gear I could then acquire from junked cars or order from the factory for my own. For 99% of the parts were interchangeable!

But maybe the best thing was the drivetrain. The combination of 351 Windsor engine and FMX transmission. Though they weren't the fastest power trains in Ford's stable, they were among the very toughest, and perhaps the best balance of power and reliability to weight and size Ford had ever offered.

And damn if some sources today don't say that auto trannys like mine actually were faster than straight-shifts. for things like drag racing! Back in the 1970s, everyone believed the opposite of that!

|

It turns out Shadow had more in common with professional Mustangs being raced on the Trans Am circuit in 1969 than I ever knew in the seventies. For instance...

"...The prototype Trans-Am Mustangs were originally 428 Mach 1's, these seven were basic 351 4 barrell fastbacks with 4 speeds..."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

"The 351W was produced from 1969 to 1997. It was installed in everything from Mustangs to the full-size cars, and all the way up to the F350. It has been one of Ford's most successful engines."

-- Ford Windsor engine ["http://www.answers.com/topic/ford-windsor-engine"]; 4-1-07; answers.com

"The FMX...is a rock crusher tranny and will take more abuse than anything Ive ever seen."

-- Ford Cruise-o-matic, 5-24-08 ["http://www.hotrodders.com/forum/ford-cruise-o-matic-53163.html"]

Though in my day the common belief was the opposite, it now appears auto transmissions were actually faster than straight-shifts in some cases-- even at the drag strip!

I basically stuck with my own auto trans for budget reasons, plus what I felt was 'good enough' performance. Too, I liked the extra freedom I had by not having to babysit a shifter arm and clutch pedal, and felt like that allowed me to concentrate more upon my driving.

In hindsight, I'm pretty sure owning a straight-shift transmission would have killed me back then. For there were too many cases where the extra distraction and effort required for constantly shifting gears would have left me vulnerable to all manner of threats and road hazards.

"Surprisingly, the 13-second timeslips came from automatics, while the four-speed cars were in the low-14s"

-- 10 Fastest Mustangs

"Manually shifted transmissions are an endangered species. In 1980, more than 35 percent of cars sold had a stick; in 2007 the number had dropped to 7.7 percent."

"...it's widely believed that manuals are more fuel-efficient than automatics. Sorry, that's no longer true."

"Another myth is that manuals accelerate faster. Wrong again. The Porsche and other models are faster with computer-controlled trannies. These automatics shift so quickly that no human being, not even the world's best drivers in Formula 1, can match their abilities."

-- The End of Manual Labor? The stick-shift is a fast-fading icon.

By Lawrence Ulrich of MSN autos

|

I wrecked the car myself a few times as I tried to come to terms with having so much power under my right foot as well as the surging hormones of an American teenage male.

Having little money forced me into trying to do some repairs myself-- which may well have been the spark lighting the modification fire. My dad often lent a hand too, being a junkstormer from way back.

Modifications I made to Shadow included those below (presented in utterly random order):

Installed a transmission fluid pan drain plug the first time I changed both the fluid and filter in the FMX transmission.

Above is an artistic rendering of Shadow's solid steel custom rear spoiler (There are no good photos of Shadow's tail in existence today). I say solid steel because I first made thin cardboard templates of how I wanted the shapes to be, then cut out matching steel forms. Those were then bent and shaped as needed to fit properly and be attached. I did use a bit of brazing and bondo to smooth over seams, rivets, and the like I believe.

| |

Stability improvement. Designed and fabricated a custom supplement to the existing rear spoiler on the car, from galvanized steel, to exert downward pressure on the car's rear tires at speed (to improve handling). My custom shaped steel extensions were pop riveted to the corner posts and steel trunk lid of Shadow, then worked over to appear seamless on the car. This spoiler supplement was of the wraparound or apron variety, similar to what could be seen on Pontiac Firebird Trans Ams of the seventies. It definitely was NOT a wing type as was optional on Mustangs, nor the slanted plane seen on some factory Camaros of the era.

I seem to recall being surprised to discover factory fiberglass versions of my own Mach One pot metal rear corner posts, maybe off a junked Boss 302 Mustang(?) and acquiring them for Shadow. These were lighter than the pot metal versions and easier to work with mod-wise. I remember doing some brazing around the trunk lid (maybe to cover rivet heads?) and a molten metal drop falling onto my shoe, there burning through into my foot before I could get the laced shoe off. It took decades for the scar to fade to insignificance.

Above a poor quality photo of Shadow's custom front air dam, grill, and hood (among other things).

| |

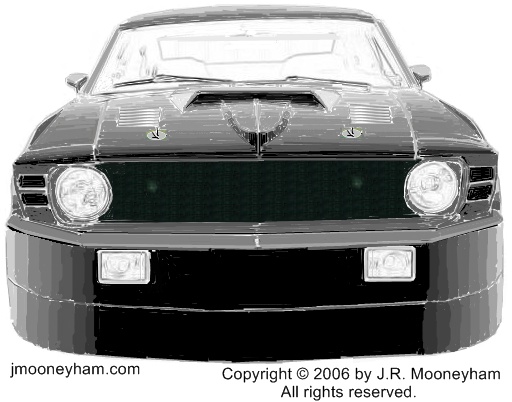

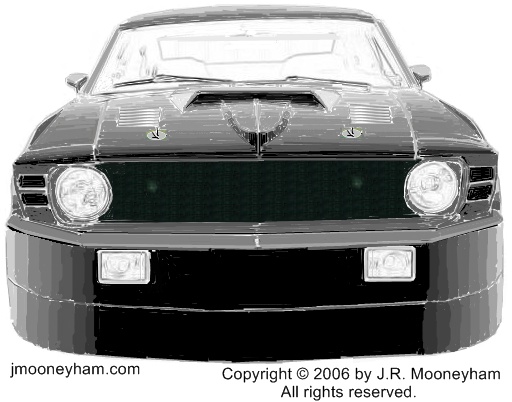

Stability and night-time stealth improvements. Designed and fabricated a custom front air dam and extra large front fender flares to accomodate wider tires, from galvanized steel, fiberglass, and rubber sheeting (a mere two inch ground clearance for the air dam's lower component (when installed) is present in my notes). Notice the bottom half of the air dam was flexible rubber, made from an old factory conveyor belt maybe a quarter-inch thick and painted black, so it could easily scrub the ground at times and bounce right back. But the rubber was sufficiently stiff-- especially with a central crease I purposely forced upon it by how it attached to the steel upper-- so that it wouldn't bow much to air pressures over 100+ miles per hour.

Above is a full on head on view of Shadowfast's final front end appearance, with the lower rubber air dam installed (artistic rendering).

| |

How was the lower flexible dam attached to the steel upper? The rubber sheet extended maybe two or three inches up behind the steel upper when installed. I had a strip of steel of roughly this width which spanned the entire upper dam behind the top edge of the rubber sheet. Holes were drilled through the metal strip, the rubber sheet, and the steel dam upper, maybe every two or three inches. Suitable nuts and bolts fastened it all together. Of course although this method was darn strong, it also meant installing or removing the lower flexible dam required maybe 20-30 minutes. I guess I could have replaced the nuts and bolts with some quick-release gizmos, but I never got around to that.

This attachment was strong enough that on an early visit to college (before I was enrolled I believe) while navigating the unexpectedly narrow streets and high concrete curbs on-campus my lower flexible dam got caught between one of my wide front tires and a curb, and as the tire rolled forward pulled down on the rubber sheet. This tore one side of my steel air dam loose from one fender (the right-hand side I think). Keep in mind this stuff was at minimum pop riveted and fiberglassed together-- maybe brazed(?) with bondo over that to smooth it out. So it took a lot of pressure to bust it that way. This happened maybe 150 miles from home, with me needing to return that same day.

What did I do? It was relatively easy to improvise a temporary repair with a coat hanger (or wire?) of the damaged side. Maybe a five or ten minute job. I don't think I even removed the lower flex dam for the trip home. I'm pretty sure we (I had a friend with me) averaged 100 mph the whole way back on the interstate, mainly slowing down once getting two thirds of the way back because there's a big city there, and heavier traffic. The temporary repair basically had Shadow's aerodynamics back to near 100% again. I believe I had the dam permanently repaired by the end of the next day.

a - j m o o n e y h a m . c o m - o r i g i n a l

If needed the bottom half of the dam could be removed for easier rough road passage. But the air dam was also protected another way: for Shadow's springs simply couldn't let the car descend beyond a certain distance towards the ground in a bounce. I had stiff rubber spacers (as well as aluminum ones) inside the front coil springs which forced a minimum ground clearance onto Shadow's front suspension, as well very limited bouncing around. This minimum clearance also served to protect the engine oil pan and trans pans from scraping the ground in bad bottoming out events (though maybe this made things worse somehow for the front shocks; it seems I busted a shock mount once). The blockage of air flowing underneath the car forced more air towards the engine's ram air scoop plus through the front grill for engine and trans cooling, then out and over the hood through the louvers. At high speeds the combined effect of the air dam and rear spoiler made Shadow 'hunker down' and stick to the road better. The wider tires helped too. CAVEAT: The wider tires all around made Shadow more prone to hydro-planing on very wet roads. It hurt in traction on snow and ice too, but I mostly remember hydro-planing problems where water was standing or flowing over the highway. END CAVEAT. Note that this air dam addition basically replaced a lot of standard bodywork in that area of the car, which previously included a couple signal lights, a couple running lights on the sides, an under-the-bumper cowling and factory-type spoiler (well, the spoiler may have been torn off already by then due to some rough driving) and maybe a few internal brackets which helped hold all that stuff together. As I still needed some signal lights in the front I installed a couple general purpose versions behind the new custom mesh grill (I think maybe these things were billed as 'fog lights' at Big K or something?). I didn't replace the side running lights with anything at all, in keeping with the desire for greater night-time stealth.

|

Hmmm. Turns out the racing pros had experimented with air dams and extra large fender flares on the '69 Trans Am Mustangs too! Of course I may have been unaware of that several years later when I was trying to finalize my own design...

"The stakes were high in 1969. It was manufacturer against manufacturer. Winning was going to require more sophisticated methods. The Shelby cars were wind tunnel tested and prepped further by Shelby's veteran team...Lots of other new ideas were used like as front air dams,....fender flares and rear wing-spoilers."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

|

I guess I could have rigged up an additional circuit to allow me to use the fog-cum-signal lights for full-blown sustained light sources to supplement my headlights and driving lights still further at times, but I never did. Of course, in a real jam where I'd lost both sets of my other forward lights I was well able and equipped to reconfigure the fog light set up to temporarily replace them.

Weight reduction. Replaced standard hood latch mechanisms with hood pins to reduce weight and improve maintenance access. NOTE: I believe Shadow already had hood pins plus standard latching system when I bought him, and I merely later removed the standard latch gear for weight reasons. But it's also possible I installed the hood pins myself. I simply cannot recall which with certainty. END NOTE.

Security improvements. Partially installed an anti-theft system (just the siren). Why did I stop short on the siren related security system? Time and cost-effectiveness, mainly. A complete install would have required an inordinate amount of work for what little added security I would have gained. Because it was necessary to install reverse switches in both doors, the trunk lid, and hood. Locating hard-to-determine sweet spots for the switches and their tolerances in spaces normally hidden behind or underneath various closed hatchways. Drilling new holes, sometimes through some of the thickest metal on the vehicle. Running a whole other wiring harness throughout the car, maybe requiring new holes of its own. The reverse switches would often be located in spots likely to get wet a lot. So corrosion and malfunctioning and run down batteries were a distinct possibility. And the installs would have required careful adjustments at every switch to insure proper working. Frequently. Trial and error. For weeks or months. False alarms would have been God-awful for any of the different neighborhoods I lived in at the time.

Of course I did not realize all the work and bad possibilities involved until after I'd bought the thing and checked out the instructions and gear.

The siren worked well though!

Other security measures included small padlocks in the hood pins and an anti-siphoning spring in the gas tank filler tube. Other items in this category included things like a motion sensor and mag wheel locks. The motion sensor was way too sensitive (causing false alarms) so was quickly removed. The mag wheel locks proved too much of a nuisance for an inveterate hot rodder like myself, and so were soon discarded as well. I eventually rigged an unusual step into the starting process too to foil would-be thieves in that manner. I actually experimented with electrifying the entire outer metal skin under some circumstances, but decided against adding that trick to the car (you might be surprised at the nasty jolt which could be delivered in that fashion). This contingency just seemed too unlikely to ever be used for anything worthwhile, plus there were several awful ways it could backfire on me. Or maybe even hurt innocent folks.

Stability and cooling improvements. Embedded the steel vent louvers from a house's air conditioning case into the hood, to encourage better air flow through the front grill, radiator, engine compartment and reduce air flow under the car and improve cooling capacity at speed. They looked pretty fierce, too.

Horsepower boost. Replaced the original small fake scoop with a larger 429 Boss scoop. Cut a hole in the hood to activate ram air flow; Cut a portion of the existing air cleaner set up to accept the air flow (but still filtering it). Used rubber bicycle tire(s) cut to fit to create a flexible seal between the air cleaner and the hood upon closing. This arrangement was designed so the air cleaner could be replaced as desired by an aluminum velocity stack which fit closely to the hole in the hood (for races only). May have used some weatherstripping too to aid sealing.

To see more info (including imagery) regarding this design, check out Shadow's ram air system.

Cooling improvement. Installed a dedicated aluminum transmission fluid cooler, taking the burden off the main engine radiator and increasing trans cooling capacity

Cooling improvement. Designed and installed an improved radiator fan shroud to improve cooling efficiency and engine compartment maintenance access.

Cooling improvement and horsepower boost. Replaced the standard steel fan with a lightweight aluminum flex fan to reduce unnecessary engine drag at speed, while improving cooling at low speeds as well.

Weight reduction and night-time stealth improvements. Removed much of the factory standard chrome trim, insignias, and ornamentation for both weight and appearance purposes.

The true source of this page is

Night-time stealth improvement. Painted entire car including all remaining chrome light-absorbing flat black for improved stealth capacities at night; this also made it easier and cheaper to paint over new repairs or modifications

Replaced front 1969 quad headlight cowls with 1970 twin models

Cooling improvement. Opened the fake scoops in the 1970 cowlings to improve cooling to the front brakes.

Cooling improvement. Opened the fake 1969 rear scoops and ducted the air flow to improve cooling of the rear brakes

|

Similar to Shadow, the professional Tran Am Mustangs in 1969 used scoops to cool the front brakes too.

"A front spoiler hung under the front of the car made of ABS plastic with scoops just above to channel air to the front disc brakes."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

|

Security improvement. Added rectangular driving lights under the front bumper for safety redundancy in forward lighting (separate circuits, bulbs, locations) as well as just plain more light for high speed driving situations.

Weight reduction. Replaced front grill with quick-release custom design to improve cooling, lessen weight, improve air filtration to radiator (fine fiberglass mesh kept bugs and debris from clogging or damaging the radiator) and improve maintenance access

24-7 stealth improvement. Installed a CB radio (23 channel?) in a custom overhead console running from above the windshield to the roll bar; The radio could be swiveled to face either driver or passenger; removable antenna installed in center of car roof for maximum range and performance; there seems to have been a public address system connected to all this at some point(?) with a speaker under the hood somewhere(?) or maybe it was something to do with an anti-theft system, according to my notes. I can remember testing one too. But I don't think I ever used the loud speaker any other time. I may have removed it again at some point for weight reasons.

I tested different CB antenna configurations to determine which one would serve me best. I finally settled on one antenna mounted in the center of Shadow's roof as having the greatest range all around, but especially ahead and behind. I could easily remove the antenna when desired.

Installed an AM/FM radio/tape player behind the floor console, in the inclined panel reaching from the floorboards to the horizontal carpeted rear shelf in the back. It was a bit inconvenient as I had to turn away from the road to look at it, but usually I just shoved a tape in and forgot about it anyway. And could do much with it just by touch alone. The player's controls could be seen smack in the middle of the inclined panel, directly between the two front seats and over the driveshaft hump.

24-7 stealth improvement. Replaced the bullet-style passenger side door rear view mirror which seemed to have been lost along the way on the car

Security and handling improvement. Welded a roll cage into the passenger compartment; bars were steam pipes bent to fit if I recall

1-10-05 UPDATE: After having some time to think on it, I believe I welded the roll cage into the car at seven spots rather than the four I initially recalled. Two places behind the front seats (one at each side of the car, near the rear of the door openings), two into the rear of the extended passenger compartment, two more spots where the roll bar curved around to run across the underside of the roof: I welded in stubby pipe pieces as connectors between the steel framework around the roof's perimeter and the top rounded corners of the main roll bar beam. And lastly, another bar welded into the system at something like a 45 degree angle, attached between the door opening and the passenger seat to the floor, with the upper end attached roughly mid-way up one vertical leg of the main roll bar beam itself. This 45 degree angled bar slightly obstructed people getting into the passenger side of the car. Why in heck did I put such an extra bar there and not on the driver's side? Basically because I wanted better protection for a girl friend there. And greater convenience for myself in getting in and out of the car, as I did that so very often. END UPDATE.

|

Compare my mouse squeak budget amateur roll cage efforts with the zillion dollar professional racers of 1969...

"A mandatory roll cage was extended to stiffen the body....The suspension of the Trans-Am Mustangs was pure race car. Trans-Am rules prohibited moving the suspension mounting points, so the roll cage was welded directly to the car suspension mounting points for strength."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

My own roll cage didn't tie in directly at the front suspension mounts like the Trans Am racers might have from the sound of things above, but they came awful close to the same arrangement in the rear, attaching to the top of the frame rails very near the top rear shock mounts. I also welded my roll cage to points attaching it to the heaviest floorboard metal just behind the front seats (I think the front ends of the rear frame rails were just underneath there in my unibody car), to the roof top perimeter frame, and with an additional strut from the passenger side main upright to the floorboard between passenger seat and door, at roughly a 45 degree angle.

|

Padded the roll bar where possible with foam rubber pipe insulation

Replaced steel valve covers with aluminum ones In hindsight I'm not sure I'd do this again. The new covers were finned and chrome (or polished aluminum?) and made the motor look prettier, but I seem to recall them being much thicker and considerably heavier than the nice functional covers they replaced. They also seemed to exude a lot more heat than the original covers. Hopefully this meant they helped the motor run cooler (and so were worth more than mere looks for their extra weight burden), but I'm not so sure. I mainly remember them seeming to take up a bit more room in the engine compartment than the older covers, and burning me more often. OW!

Weight reduction and horsepower boost. Replaced heavy factory exhaust manifolds and system with lightweight headers and straight through mufflers

Stability improvement. Added heavy duty chrome traction bars (would later paint them black)

|

Believe it or not I don't think I ever knew the professional Trans Am Mustangs in 1969 used traction bars like me, until I found the tidbit below in early 2006(!)

"The suspension of the Trans-Am Mustangs was pure race car....Traction bars were welded in above the leaf springs...."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

|

Stability improvement. Replaced the standard rear leaf springs with salvaged Boss 302 springs

Added adjustable brackets to the rear leaf springs which gave me the option of raising or lowering Shadow's rear end without the need for air shocks or other means. Unlike most of my peers of the time I never raised Shadow's tail end simply for looks as was the fad of the time. However, I liked the idea of having flexibility in this area for other reasons.

The true source of this page is

Installed clamps to the rear leaf springs to reduce sideways movement of the different leaves amongst one another. Apparently I did this to further reduce the chance of body sway atop the suspension in curves. I only did this after discovering the leaves actually shifting about that way.

|

Wow! Another 2006 surprise to me was to discover the pro 1969 Trans Am Mustang teams were trying to restrict sideways movement of their leaf springs as well(!)

"The suspension of the Trans-Am Mustangs was pure race car....The leaf springs had a Watts linkage added that restricted the side to side movement, allowing the spring to move vertically only."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

|

Stability improvement. Replaced the standard small front anti-sway bar with a new Boss 429 anti-sway bar

|

From the quote below it appears the 1969 Trans Am pro teams beefed up their front anti-sway bars beyond Boss 302 level too...

"The suspension of the Trans-Am Mustangs was pure race car....The cars were aligned perfectly to the computer specifications developed by Kar Kraft for the production Boss 302's...[but?]....Thicker front stabilizer bars were used...."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

"In case you don't know the original Boss 302's story, here are the CliffsNotes: It was introduced in 1969 as a road racing car for the street."

-- 2012 Ford Mustang Boss 302 First Drive and Video Just Your Everyday Ass Kicker By Josh Jacquot; Feb 24, 2011; insideline.com

|

Stability improvement. Added a rear Boss 302 anti-sway bar salvaged from a junked Mustang (Shadow previously had no rear bar at all)

|

Some racing purists will point out that solid rear axle cars are typically at a disadvantage against independent rear suspensions in handling, and in general this is true. But if any rear solid axle car could have given any independently sprung auto a run for its money handling-wise, it would have been Shadow. For I simply hit the sweet spot in all my mods to the car.

When reading about a new generation of solid rear axle Boss 302s from Ford, I ran across quotes which seemed eerily reminiscent of how Shadow himself drove and handled. Quotes such as this:

"Sure, get aggressive on an uneven back road and the chassis will still let you know there's an axle out back — but not before you've gone faster than just about everything else."

"...you're not going to go this quickly in anything else for this kind of money."

-- 2012 Ford Mustang Boss 302 First Drive and Video Just Your Everyday Ass Kicker By Josh Jacquot; Feb 24, 2011; insideline.com

|

Stability improvement. Replaced the standard rear shock absorbers with heavier duty coil-over shocks (not air shocks). With the kind of hard driving me and my circle did I saw air shocks bust all the time. Plus I just thought it was silly to install air shocks just so you could raise your car's rear end high into the air and ruin its handling, as well as make it easier for cars behind to run underneath you in a collision. Agh!

Added two stereo speakers to the newly fabricated rear-most wall of the passenger compartment, which was also the new front-most wall of the shortened trunk

Security improvement. Added better gauges for water temp, ampmeter, and oil pressure

Security improvement. Added a tachometer

24-7 stealth improvement.Replaced standard interior rear view mirror with a wide-angle similar to that used in some stock car racers of the time; it offered a 180 degree rear view (or near it) all on its own; the extra mirrors on the doors provided backup and a bit of a supplement

Note I fully removed the standard interior mirror for this. And even its metal mount which was glued to the windshield at the factory-- after I'd had the wide-angle long enough to know it worked great. I believe lacquer thinner (?) did the trick. Although it's a hazardous material, I seemed to use it a lot for various work related to Shadow. It was also great for removing decals from windows, etc.

Replaced standard steering wheel with a smaller, padded custom wheel (Note that Shadow's possession of power steering made this move OK) The original factory wheel was a rim-blow, which meant you could press anywhere inside the wheel ring to blow the horn. This feature deteriorated with age though, finally one day making the horn blow constantly. That forced me to disconnect the horns under the hood. Completely replacing the factory wheel allowed me to regain horn use again with the much simpler and better working central horn button on the wheel: i.e., no more rim-blow.

Weight reduction. Replaced original dashboard with a custom designed dash, to lessen weight and add more switch capacity, among other things; the new dash was based on the 1960s GT-40 design. As discussed elsewhere on site, this mod proved to be one of the toughest on the whole car for me.

Replaced my dingy white factory seats with much nicer looking black leather seats from a 1971 Boss 351 Mustang

Weight reduction. Replaced entire original interior with a custom designed interior converting the car into a two seater with a spacious deck in the rear suitable for sleeping two. This reduced available trunk space, but additional storage was available under the new deck via three access doors. Black shag carpeting was installed over the deck and floor boards. Flexible, lightweight wooden panels were cut to easily snap into and out of place throughout the new interior, and coated with black crushed velvet cloth. Note this whole interior replacement involved the removal of a lot of weight from the car, including some large heavy metal panels which previously separated the interior from the trunk

Stability and security improvements. Extra long battery cables were procured and quick-release terminals installed on them to allow the main battery to be moved from under the hood to underneath the deck inside the passenger compartment for improved weight distribution and easier maintenance access to the engine compartment. A double door opening in the horizontal deck and an inclined panel between the deck and floorboard just behind the two front seats gave battery access. This new battery compartment was designed large enough to contain a spare battery too-- but I never got around to adding a second. Quick-release corrosion-resistant terminals were installed on the battery cables. Note that batteries in those days were high value targets for theft, so moving my battery to this unusual location probably increased my general automotive security quotient.

CAVEAT: This move of the battery meant much longer cables were required, which also meant a greater drain on the battery in general. During winter cold conditions this often caused me starting problems. I may have at least partially solved this via use of more expensive battery cables and a new, more powerful battery itself at some point. In my most pinched moments I may have used ether spray down the carb to make for easier starts. I believe I first moved the battery all the way back into the trunk (using a cable as long as the car) trying to get the best bang for my buck weight distribution-wise. But that's where I experienced the most trouble with starting, especially in cold weather. Plus the battery really took a beating back there in violent manuevers, despite being well attached. It wasn't unusual for fluid to leak during such times, forcing me to have to add water afterwards (in those days auto batteries often required users to check their water levels and top them off). The battery's position was problematic back there due to tool and spare parts storage too-- as well as being a potential spark-maker basically sitting atop my gas tank. Yikes! So eventually I switched to a shorter cable and moved the battery more towards the middle of the car as described (installing it in a custom storage compartment of its own just behind the front passenger seat, in close to the safest place in the whole car in terms of the roll cage). END CAVEAT.

|

Note that moving the battery was just one of the things I did which tended to change the weight distribution on Shadow. Of course, I doubt I was ever able to get Shadow to a true 50/50 distribution front and rear, like a professional Trans Am car or expensive mid-engine Lemans racer or other exotic sportscar, such as certain Ferraris. But my own experience makes me wonder how modders like Shelby ever did such a thing themselves. For in my own case I think I'd have to have moved all my cooling radiators into the rear of the car, and moved the entire drivetrain (engine and transmission) back a few inches as well...Sheesh! Did those guys do stuff like that? Such major mods were well beyond my own finances and resources of the time.

Of course, if Mach 1 Mustangs were closer to 50/50 weight distribution than I expect from the factory, then maybe I'm overestimating the mods required-- and so perhaps I came closer to matching the pro cars than I thought. Shadow sure did handle awfully well, whatever the truth of the matter!

5-27-08 UPDATE: One source says the 1969/1970 428 Cobra Jet Mustangs had a 59%/41% weight distribution on the front/rear wheels from the factory. However, 428s were big blocks, and certainly heavier than my 351. Though maybe not as much heavier as you'd think! Yikes! According to one source there was as little as a 29 lbs difference! But maybe that stems from the Cobra having a lighter straight shift transmission compared to my auto, and lighter front disc brakes than my big drums. It might even be the Cobra had a lighter intake and exhaust manifolds than my stock Mach 1 too, as some hot rod parts were applied at the factory to such motors.

"..rear tires, which suffered from a 59/41% f/r bias which also hurt handling..."

-- 1969 Ford Mustang Ford Mustang History: First Generation 1964 1/2 - 1973

The best estimate I have for a Mach 1 like Shadow from the factory was 3571 lb. According to one source, the 1969 Ford Mustang Mach 1 428 Cobra Jet weighed 3,600 pounds. Or only some 29 lbs more for the big block.

-- 1969 Ford Mustang Mach 1 428 Cobra Jet

by the Auto Editors of Consumer Guide

So I guess I'd have to figure Shadow's starting weight distribution was roughly the same as the Cobra's. Or only slightly better (by 29 lbs).

However, I reconfigured the distribution with my mods.

Specifically, from over the front wheels I removed the battery, replaced the stock exhaust manifolds with very light headers, replaced the standard intake manifold with an aluminum version maybe a third of the weight, removed the hood latch gear (to rely only upon the hood pins), replaced the factory grill work and braces with a much lighter custom fab job, and replaced the heavier quad headlight front end with a dual set-- from which I also removed plates which kept the scoops closed. I cut a hole in the hood for my scoop, replaced some hood sections with louvers, and drilled holes in various spots within the engine compartment walls to lighten it further. I also replaced the steel cooling fan with a lighter aluminum job.

Heck: I even removed the radio antenna from the right front fender! (Replacing it with a combo radio/CB antenna in the middle of the roof)

Other things I did which took some load off the front wheels was to replace my factory dash with a much lighter custom fiberglass version-- and remove entirely the heater core.

As for the rear wheels, the weight changes may have been more of a wash, although I did perform some weight reductions there too. I say a wash, because of the movement of the battery from the front to the rear, the installation of the roll cage and rear shelf to replace the factory interior and a steel bulkhead, and the addition of a comprehensive kit of tools and spare parts in the trunk. Plus I added a sway bar back there, and more heft in the spring department, too. And stuff like an extra high capacity nitrous apparatus isn't exactly light as a feather, either. So the rear wheels likely didn't get nearly as big a weight reduction on them as did the front.

I have documentary evidence today for having removed

around 771 lbs net from Shadow's factory weight. Even after adding back in things like the roll cage, rear spoiler extension, front air dam, rear sway bar, heavier front sway bar, etc. Some of this weight, like at least 50 pounds of sound insulation, probably were a wash distribution-wise. And the rear interior transformation feels like it was roughly a wash too, from what I can recall.

But most all the other weight I removed or transferred was from the front, as detailed above. And seems like added up to something around 150 lbs being removed entirely off the front wheels, with some 50 lbs (the battery) being moved from the front to the back wheels.

I'm basing this on trying to remember the differences in weight of each part as I handled it. YIKES! Parts I handled roughly 30 years ago! Ha, ha.

Of course, my fading memory regarding all this isn't the most accurate measure in the world. And the Texas weigh-in indicates I may be lowballing it. Truth is, most of the removed weight simply had to come off of the front wheels' load, at least in partial fashion; because there just wasn't that much heavy stuff to remove from the rear of the car. 200 lbs would account for 7% of the total weight of Shadow after his transformation.

Divvying up how much weight removal benefited which wheel set would be a bit complicated even if I still had the car today upon which to take measurements. But I'll make a wild stab at it here.

If Shadow started off with a front/rear weight distribution of 59/41%-- or roughly 2107 lb/1464 lbs for a total 3571 lbs car-- and had kept his original ratio even at his lowered weight of 2800 lb (1652 lbs/1148 lbs), but then had that 7% (200 lbs) shifted to the rear, we'd get a weight distribution of 1452 lbs/1348 lbs: or 52/48%.

Although there's no way to accurately verify it today (unless I was fabulously wealthy and able to have Shadow rebuilt for such measurements), I believe this is likely close to his actual weight-distribution in ultimate form. Heck: he might even had been slightly closer to the magic 50/50 ratio than this. However, I know for a fact that he retained a certain bit of his factory understeer to the very end-- which indicates he likely had to be around 51/49 at least (when he had a 130 pound driver sitting in him). So 52/48 is definitely a plausible figure.

And darn if 52/48 isn't a respectable ratio for an amateur-built supercar assembled on a shoe-string budget in the 1970s!

And maybe Shadow even outdid street Boss 302s in weight distribution! And practically matched that of the Trans Am race car versions! And both those Boss models were raved about as being great road handlers!

"Obviously ford wasn't interested in mass-marketing the [Boss] 302 when the mach 1 was there as the heady performance machine. False economy perhaps, because the Boss 302, equipped with competition suspension consisting of staggered rear shocks, thicker fron anti-roll bar and stiffened springs coupled with a quick 16:1 steering ratio, was infinitely a better-balanced car. Weight distribution of 55.7 percent in the case of the Mach 1 obviously helped."

-- The 1969 Boss 302

END UPDATE.

Amazingly enough, it appears I actually got Shadow down to a total weight LOWER than a pro Trans Am 1969 Mustang based on the info below(!) For during a weighing for a Texas vehicle inspection Shadow displayed a weight of 2,900 pounds-- but that was with at least 100 pounds of tools, spare parts, and other equipment in his trunk and elsewhere-- items a race car on a track wouldn't be carrying. And that 100 pounds probably doesn't include his custom interior either: another item the race car wouldn't have to tote around a race track. So just maybe a Shadow with his non-essential interior components and trunk junk removed would have weighed 100-200 pounds or so less than a professionally assembled race-ready Trans Am Mustang in 1969! Wow! Could it be my poor dad and I actually achieved such a near miracle on our teeny-tiny budget back then? Seems so!

To see a scan of the actual Texas document for Shadow's weigh-in, please visit this other page.

"It took the Shelby team six weeks to take their cars apart and and rebuild them to Trans Am specs....The car's weight was restricted to 2.900 pounds. The stock Boss 302's weighed in at 3,250 pounds. The distribution of the weight of the cars was shuffled around so that they were 50/50 front and rear...On the track, the Boss 302 Mustangs were simply awesome."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

9-18-06 UPDATE:

1970 Ford Mustang Trans Am Boss 302 specifications:

"Wheelbase 108.0 in.

Track F: 58.5 in., R: 58.5 in.

Length 187.4 in.

Width 71.7 in.

Height 47.5 in.

Ground Clearance 2.5 in.

Curb Weight 3240 lbs.

Weight Distribution 51%/49%

(F/R-with driver)

Fuel Capacity 22.0 gallons

Oil Capacity 5.0 Quarts

Water Capacity 15.5 Quarts"

1970 Ford Mustang Boss 302 Street specifications:

"Performance

0-60 mph 6.9 sec.

1/4 mile 14.6 sec. @ 97.50 mph

Dimensions

Wheelbase 108.0 in.

Front track 59.5 in.

Rear track 59.5 in.

Overall height 50.4 in.

Overall width 71.8 in.

Overall length 187.4 in.

Curb weight 3250 lbs

Fuel tank 20/22 (1969/1970) gallons

Chassis/Suspension

Competition suspension and front tower extra bracing, staggered rear shocks and power front disc brakes

Weight Distribution 55.7/44.3 (front/rear)

Front spring rate 350 pounds

Rear spring rate 150 pounds

Rear spring size 53*2.50 in. and four leaves

Shocks Gabriel direct-acting

Front stabilizer bar diameter 3/4 inches in 1969 and 15/16 inches in 1970

Rear stabilizer bar diameter 1/2 in. (only 1970)"

-- How did Trans Am cars differ from stock? [Archive] - Race Sim Central Forums

["http://forum.rscnet.org/archive/index.php?t-67086.html"]; found on or about 9-18-06

[Based on the numbers above, ground clearance for a street Boss 302 seems to have been 5.4 inches]

END UPDATE.

3-4-15 UPDATE: Well, it's turning out that Shadowfast's original design and construction is holding up lots better against later generation supercars than I would ever have dreamed possible, even going on 40 years later! Wow! For in the business news article below, folks are bragging about a $2.3 million Aston Martin Vulcan supercar utilizing all the latest whiz bang equipment and materials, weighing in at only-- get this-- 76 pounds MORE than Shadow did! Or 176 pounds more, if you weighed Shadow without his full complement of onboard tools and spare parts which were onboard during his Texas weight check! Yippie! :-)

-- Super Lightweight Supercars Dominate at Geneva Motor Show

by Hannah Elliott, March 4, 2015

END UPDATE.

|

No louvers or tinting were installed on any windows, since maximum visibility was required for maximum driving performance; especially at night This also helped me more easily spot law enforcement or other vehicles I might have been watching for.

Stability improvement. Replaced original front shocks with heavier duty units (I seem to remember having to beef up the top attachment brackets for the shocks under the hood too)

A foreshortened trunk required replacing the normal spare tire arrangement with a space-saver tire, small compressed air tank, and collapsible folding jack salvaged from a newer junked vehicle

a - j m o o n e y h a m . c o m - o r i g i n a l

Security improvement. Installed a 'kill switch' near the battery in the passenger compartment. Note that when switched off it made it much tougher for someone to steal the car. It also made it easier for me to do certain types of work on the vehicle. It was also a good safety option in the aftermath of certain types of accidents or malfunctioning hardware. Race cars of the time often possessed such switches.

Security improvement. Installed a mini-fire extinguisher on the floor console More than once, actually. For this baby got used a few times! Not just for my own car(s) but others as well!

Stability improvement. Installed high performance metallic brake linings on all wheels (possibly Lakewood brand)

Stability improvement. I re-positioned the factory shock absorber arrangement in the rear so they were 'staggered'; one in front and one behind the rear axle (I can't recall much about this, but my old notes indicate the possibility)

2-9-05 UPDATE: I had a vague memory of staggering the shocks being surprisingly easy, compared to many other mods of the time: like the car had been prepared for such installation from the factory. So that made me unsure about whether I actually performed the mod or found it already done. Now though the mystery is solved. For in recent web research I discovered Mach Ones would automatically get staggered shocks if ordered with 4-speed transmissions. The car design of Shelbys of the same year using the same frame and unibody chassis also incorporated staggered shocks. So yes, the factory had made sure to make it easy to stagger the shocks for such cases. Which explains my odd recollection. END UPDATE.

Night-time stealth improvement. Installed a blackout toggle switch for all lights not facing forward on the car, to help stymie night pursuits; included a dash indicator light to show when the stealth circuit was operating. It proved a lot tougher than I expected to accomplish this little feat in the circuitry. Mainly due to the brake lights problem.

Re-designed the fuse access panel

Security improvement. Tiny spoilers were installed on the windshield wipers as they tended to lift off the glass at high speed otherwise, letting running water impede my vision. I'd used some sort of chemical glass treatment for this previously-- but applying the spoilers obviated the need for periodic treatment purchases and applications-- and so saved me time, trouble, and money.

I may have installed a manual choke to help offset the harder cold weather starting caused by the longer battery cables

I seem to remember installing some sort of flexible necked light source in the passenger compartment, perhaps hanging from the overhead console, for map-reading purposes and others.

Weight reduction. I may have drilled holes in various places in the car's metalwork simply to lighten it more (it's in my notes). I also used a torch and tools to remove various brackets or other items made irrelevant by my modifications. I also removed much sound-deadening insulation installed by the factory.

Security improvement. I installed an extra throttle return spring on the carburetor for added safety. I personally knew of several occasions when other folks' springs failed, leaving them with a car running at full or near full throttle. One of these instances involved my best friend and his mom in a full-sized Ford or Mercury auto.

Stability improvement. I may have replaced the original front brake drums on the car with heavier duty finned ones salvaged from a junkyard (it's in my notes).

These drums may have been thicker than my originals, and so capable of taking more punishment. The fins would have helped them dissipate heat better than smooth drums too.

From my notes I'm unsure if I was using 14 or 15 inch wheels on the car at the end. The main difference between them would have been ground clearance and terrain versatility: so 14 inchers would be better for exclusive high speed use on smooth paved roads with little or no abrupt level changes, while 15 inchers would have likely been more practical for all-around use (plus add slightly to top end speed). Note that the very earliest autos which had to roam about a countryside lacking many roads at all (and what few roads did exist often barely deserved the name) usually sported wheels considerably larger than 15 inchers. The larger diameter helped the auto better roll over obstacles in its path. So the larger diameter wheels a car possesses, the more flexible it can be in dealing with wild terrain or road hazards. I believe I was using the 15 inchers at the end-- but doing so reduced my tire and fender clearance in the rear to the point of scraping at times. To reduce the scraping I tightened up the rear suspension to maybe its maximum settings and kept it there. The wheels in the front enjoyed more clearance than the rear due to their enlarged custom fender flares. But there too I tightened up the suspension a great deal.

|

I definitely had rear wheel scraping problems on Shadow at times, due surely to my use of 15 inch wheels back there without any modifications to the rear flares like was performed for the front. It appears the professional Trans Am Mustangs used 15 inch wheels too (though the specs below look a bit confusing)...

"....Twelve inch Goodyear racing tires were mounted on 15"x18" American Racing or British Mini-lite mags...The stakes were high in 1969. It was manufacturer against manufacturer. Winning was going to require more sophisticated methods....Lots of other new ideas were used like as front air dams, wider tires & fender flares and rear wing-spoilers."

-- 1969 Trans Am Racing ["http://72.14.203.104/search?q=cache:zjo_jsoFPfsJ:www.thecarsource.org/shelby/transam69.html+1969+Ford+Mustang+Mach+1+specification&hl=en&gl=us&ct=clnk&cd=71"] by Dennis Begley

updated October 28, 2000 (I found this info in Google's cache of the site on 3-20-06: the original site itself had changed to something completely different by that date).

|

Security improvement. I may have added a 'safety strap' at the forward end of the drive shaft, to prevent Shadow from 'pole-vaulting' if the front of the shaft ever came loose and stuck in the road at speed. I saw this happen to cars at drag strips, and it looked really bad.

It seems I tuned my engine air scoops with air guides of some sort to improve flow (according to my notes).

Engine collision death resistance modifications

Some folks have wondered how I made Shadow's engine more resistant to dying due to collision impacts or plain old violent maneuvers. I'm dependent today a lifetime after the fact on fading memories and old notes for the details, so the explanation is likely incomplete. But the mods below likely helped directly or indirectly in the process:

Keep in mind two principles to keep an engine firing: insure it has a steady supply of fuel, spark, and air, and its idle doesn't drop below a certain minimum. Among other things, preventing vapor lock and keeping your air and fuel filters clean can help these matters. Note that modern cars are quite different in many respects from autos of Shadowfast's era-- at least in the details of how you'd implement mods like these.

Simply having an automatic trans rather than a straight shift helped buffer the motor from drastic changes in wheel to ground contact and direction (the torque converter and all that).

Horsepower boost and vapor lock risk reduction. I may have installed an electric fuel pump (but still kept the mechanical too, if so).

I seem to have installed extra layers of gaskets in the carb to increase its local tank capacity.

Horsepower boost and vapor lock risk reduction. I insulated the fuel lines in the engine compartment, and may also have sometimes added a custom-designed cooler unit for the fuel before it entered the carburetor. The cooler can offered an extra reservoir of gas near the engine which was likely much bigger than that of the carb's own built-in supply. For the cooler can ran gas through a coil of copper tubing inside it. Cooling the gas was a common trick in dragsters for added power too.

2-12-05 UPDATE: The fuel cool can was apparently something I only used for races, and did not permanently install on the car. I think I meant to switch over to an air-cooled design from the ice one for a permanent installation, but never got around to it. END UPDATE.

Horsepower boost. Replaced original carburetor with a new Holley four barrel In some cases such carb changes helped boost horsepower-- basically by providing a bigger flow of gas and air to the motor. I believe the Holley replacement was comparable in CFM (cubic feet per minute) to the factory carbs of same-year Shelby GT-350s.

Horsepower boost and weight reduction. Replaced original steel intake with an aluminum hi-rise Offenhauser intake manifold In some cases such intake changes helped boost horsepower (as well as reduced vehicle weight). It definitely should have aided Shadow's breathing.

Cooling improvement. Installed an aluminum carburetor insulator or 'heat dissipation plate'. Perhaps purely by coincidence the new Holley carb and plate combo placed the carb exactly where it needed to be so that using either my ram-air modified air filter set up or just a velocity stack would match perfectly to the hole cut in the hood under the scoop. UPDATE: Upon further reflection I think maybe I made the happy discovery of the dissipation plate atop my old intake from the factory and simply transferred it to the new aluminum intake later. END UPDATE.

I installed high performance spark plug wires.

Installed Accell dual point distributor

Cooling improvement. I may have painted the bottom of my gas tank a light gray or aluminum color to help it reflect back heat rather than absorbing it(?)-- something like the opposite of the flat black of the rest of the car. But keep in mind that surface faced the ground under normal circumstances, so few people usually saw it. Plus, Shadow wasn't jacked up in the rear like many other cars of the time-- Shadow's ground-hugging stance kept the tank out of casual view better than most other cars of the era. I believe I actually considered insulating the tank too but never did.

Relevant effects from other modifications here. Note the ram air system fed by the large hood scoop helped insure Shadow a plentiful air supply, particularly at high speeds. The way I cut the rim off the factory air cleaner assembly multiplied the area of the air filter exposed to incoming air many times over that of factory specs too, thereby increasing air supply at all speeds plus reducing the possibility of a choke point. For in factory arrangements of that era often one small section of the air filter accounted for the lion's share of incoming air and so clogs developed easily and faster there than they could with my custom design. The massive additional ventilation of the engine compartment imparted by my hood louvers, new grill and fan shroud design, and front air dam also helped make everything there run cooler and so help prevent vapor lock in the gas lines.

Cooling improvement. Installed a coolant recovery system (I don't think the car possessed one before)

END of engine collision death resistance mods

[Caution: This page describes high risk behavior. The author strongly recommends no one try to emulate the driving maneuvers written of here.]

Back in Shadow's day the radar detectors didn't seem very reliable, or else the troopers were frequently coming up with ways to set traps where such detectors couldn't alert you until it was too late. So I think I only briefly used such a detector myself. So long as you made good use of it, the CB radio was much better for this purpose. Police band scanners too: so long as you had the proper crystals for the local area. Many years back police forces would sometimes change their crystals to stymie scanner use. Only by determining the new crystal IDs and replacing your old ones could you keep up. Last I heard it's much tougher to come by such scanner configurations these days. Even as digital scanning enabled some new eavesdropping powers for consumers, various laws were changed to prevent such listening in. Someone told me years back that consumers in some jurisdictions can no longer easily buy even digital scanners which will allow them to listen in to police radio broadcasts: that such products were banned.

Good thing I have no need for such gear today!

But with both the devices you had to be careful about misinformation or worse. Troopers could broadcast on the CBs too, pretending to be truckers or other non-police folks to purposely set you up for a trap. Heck, at times you could even get a plain old citizen prankster on the radio trying to trip you up. Or you might anger another driver by passing them too fast or in a risky manner, and they might conspire to put you in police sights if they could via the CB. Or if anyone on the road (including truckers) thought you were driving erratically or endangering them or others, they'd lead the authorities to you quick via the radio. Yikes!

Even on the scanner the police could put out wrong info if they suspected someone they were after was listening in.

Another important point was knowing the ten-codes. The messages picked up on a CB often included lots of ten codes-- 10-this, 10-that. These codes were used both to relay maximum info in the shortest time and reduce mis-comprehensions over an often static-prone channel. You could still use a CB without knowing hardly any of the codes, but serious CB use demanded memorization of many of them.

a - j m o o n e y h a m . c o m - o r i g i n a l

The police used ten codes too. For similar reasons as CB users. But police and fire personnel also use codes partly to deter casual listeners from swarming to accident scenes, and to prevent outlaws ignorant of the codes from gleaning useful info from their transmissions. So robust police band scanner use required memorization of many codes too. The same ten-code heard over CB didn't necessarily mean the same thing on a police band, though. So getting the two mixed up could easily prove a critical mistake.

Note that radio codes were sometimes localized too: that is, a particular code might not mean the same thing in Nashville Tennessee as it did in Houston Texas or Atlanta Georgia. You ignored such differences at your peril. Yikes!

Another handy skill to have was recognizing likely police cars of both the marked and unmarked varieties at a distance-- and even at night, by cruise lighting patterns alone. I excelled in this. Maybe partly because of my artistic skills. But mostly because of all the practice I got. Keep in mind that besides all the running around I did in Shadow I also rode around a lot with other people pushing the envelope on what local law enforcement would suffer.

After I added the wide angle rear view mirror to my dual side mirrors arrangement, it became almost impossible for a police car to come up close to me from behind without me knowing about it.

Of course these days (2005) law enforcement uses a much wider spectrum of automobile models than they did in the seventies, so that it's much more difficult to get such a highway advantage over them.

In the old days races and pursuits among competitors might last awhile-- but anyone being chased by real cops needed to end such a thing pronto. In drawn out chases sooner or later a road block would get you, as officers could simply radio ahead of you to set a trap. Radio waves travel at the speed of light: nobody's car will ever be able to beat that.

That is, a road block would get you if you were lucky; if you were unlucky you crashed your car and maybe got pulped in the process. Ugh!

So the key to such races was ending them ASAP. Brute speed and awesome cornering power could help in some cases to put enough distance between you and pursuers so that you could then change tactics to get away. And by change tactics I mean suddenly stop short and duck into a hidey hole so those after you would pass you by unawares. Or turn off onto an unexpected road so you didn't end up ensnared in the inevitable road block to be set up on your previous course.

But there were plenty of caveats with all this, even in the seventies. For instance, state highway troopers often possessed cars which were themselves hot rodded both engine and suspension-wise. So making your getaway on an interstate for any great distance at all could soon turn into a game of chicken with you and a trooper to see who would blow up their car or crash first.

Let me tell you, you better think twice or more before playing chicken with a trooper. Sure, you'll almost certainly outdo them in foolishness, but courage and cool thinking at high speed-- plus training and experience at such velocities-- are whole other matters.

Combine the above with their often hot rodded cars, and you might get few chances to escape their sight long enough to duck into a hidey hole or onto another road without them seeing it. And I'm talking of sustained pursuit speeds of well over 100 mph here for both of you, for extended periods of time-- unless the trooper got reinforcements or a road block ahead to help him out. Yikes!

Many factory-standard consumer cars couldn't even reach such speeds in the first place-- let alone run at them for extended periods. So the contest ended pretty quickly for most who challenged the troopers this way.

The troopers also often had reinforced front bumpers. By which they could literally knock you off the road. They could run up behind a fleeing car and bump them, causing the rear wheels to lose traction and the car start to fish-tail. Inexperienced drivers would then usually panic and over-compensate, causing themselves to lose control and fly off into a ditch or something. End of story.

And let us not forget the troopers could also sideswipe you to run you off the highway, or shoot out your tires, and all manner of other things to get you stopped. If they could get close enough to you.

Did Shadow and I ever make good escapes from these formidable officers of the law and their souped up machines and expert corraling techniques? Well, for many reasons I better just say that lots of troopers-- across several states-- witnessed Shadow traveling at substantial velocities while I owned him. But I don't recall ever having one standing beside my super car writing me a ticket. And Shadow was never impounded, or I jailed. Of course that's not to say that I didn't get nabbed in other vehicles during that time and after. There were several times I was merely a passenger in other people's cars which got into hot water-- some instances as memorable as a feature film in their own right (egads!). But being in Shadow in his supercar days was about as close as you could get to having a hot rodder immunity card against incarceration.

I have no idea (circa early 2005) what might have happened to Shadow and his subsequent owner(s) in this vein.

CLICK HERE to see a sampling of concept sketches I made of various aspects of Shadowfast while in process of designing and building him

CLICK HERE to see how I built Shadowfast for surprisingly little cash money.

CLICK HERE to see how you could get a nice headstart on building your own Shadowfast clone by starting with a 1969 Shelby GT-350

CLICK HERE if you'd like to see what it was like driving Shadowfast. CAUTION: These accounts are not for the timid!

What could have been:

Shadowfast "X" designs

| Coming Soon! |

|

Build a legend

Why did I build Shadowfast?

Basically because in my teens and early adulthood there wasn't enough other things to do with my time. Plus, it was exciting to hang around racing events and race on occasion yourself, or even see how fast you could take a particular curve. I read a lot of car magazines in those days.

Pushing yourself and your car through competitions or plain old curvy roads at speed weren't the only challenges to be had here. There was also the challenge of designing and building autos better than those of your peers, and perhaps better than could be bought from the factory. Meeting such challenges also gave one a good reason to explore new ideas and learn new skills. I bought a torch and arc welder along the way, managing to use them effectively after some practice. I learned a lot about automobiles in general, and how to troubleshoot various problems, which vastly increased my self-sufficiency and personal freedom. I learned how to design and fabricate my own custom gear, be it from metal, wood, fiberglass, or other materials, and have used those skills frequently ever since.

I also learned some basic economic and engineering principles regarding cost-effectiveness, and substance/functionality/performance versus style/looks/superficiality.

Lastly, building Shadow also forced me to assemble my own collection of hand tools. Another milestone which has helped me immensely in the years since. There's been several times I was forced to start over from scratch tool-wise in various places long after Shadow was gone from my life, but with the savvy gained from my Shadow days I can walk into any suitable store and build a fabulously capable tool collection with zero waste of time and money. I know what works and what doesn't, and how just a few essential tools can make many others redundant.

One of the many innovations I made relating to Shadowfast was the creation of two entirely separate tool kits for the car. One a feather-weight minimalist kit for maximum performance runs or races where weight and bulk could be significant issues, and the other a heavy duty comprehensive kit for long distance cruises. The small kit was basically an emergency collection which could fit entirely in a glove compartment or console box, and perform many common auto-related repair, replacement, or maintenance tasks in a pinch. But of course its utility was limited by its size and weight. The larger kit needed one or two good-sized tool boxes and a trunk for storage-- but could be used to perform many major operations on the car with no outside help whatsoever. In practice I also carried an array of replacement components in the large kit, such as radiator hoses and fan belts [CLICK HERE to read of the pocket tool kit which evolved over time from Shadow's original minimalist collection].

What secret weapons did this car possess to stymie pursuits and more?

What might a 21st century Shadowfast be like? One with all the benefits of thirty years of automotive tech advances since the original? And no expense spared in the new design and build? Check out some candidates via the link below!

A Shadowfast Mustang supercar for the 21st century

Other Mustang projects on the web:

"Traditional gas engines operate at 8 to 10 percent, efficiency, while the engine on the Mustang, he said, is at 38 percent efficiency."

"Pelmear told television station WNWO that the car hasn't traded power for miles per gallon. Pelmear said the car has 400 horsepower, goes well over 100 mph and can go from zero to 60 mph in three seconds."

-- Engineer Gets 110 MPG Out Of '87 Mustang Ohio Man Competing For $10M Prize ; July 2, 2008

| 1984 Mustang GT - How to Build a Budget Race Car |

2005 Ford Mustang GT - First in the 12's |

| 2001 Ford Mustang Bullitt - The Cure |

Fast Forward Fastback Mustang |

2005 Ford Mustang Fastback |

| Mustang Makeover 1969 Mach 1, Part I |

1969 Mach 1 Mustang Makeover - Part III |

| 1969 Mach 1 Mustang Makeover - Part II |

1970 Ford Mustang Boss 302 - Thoroughbred Restoration |

| 1968 Ford Mustang Fastback - Realizing a Dream |

1966 Ford Mustang Project Car - Project Build - Mustang Monthly Magazine |

| Mustang & Ford Project Cars - Muscle Mustangs & Fast Fords |

Jason's Mustang Restoration Project |

| Mustang Project |

1969 Mustang Special Project |

Jerry's 1969 Ford Mustang Mach 1 |

| Yarg's Classic Mustang Restoration Project |

| Eleanor-inspired Mustang Fastback |

| StangNet Mustang GT500 Project |

1968 Mustang Project KISS - Mustang & Fords Magazine |

| Sub 2500 lbs. 96 Mustang Cobra Project... - Corral Forums |

Ford Mustang Restoration. Classic Ford Mustang Stories. | |

67 Ford Mustang Restomod Project |

Project Progress Forum - 1969 Mustang Supersite Web Forums |

| 2006 Ford Project Mustang GT |

Mustang Project Guide - 5.0 Mustang & Super Fords Magazine |

| FordMuscle webmagazine: Mod Science - Introduction to our 2001 Mustang GT Project Car | | 1969 Ford Mustang Mach 1 - Duke's Hazard | 1969 Mustang Special Project | | 1968 Ford Mustang Fastback - Realizing a Dream - Mustang Monthly ... | 1969 Mach 1 Mustang Makeover - Hot Rod Magazine | |

Bill Genard’s ’70 Mach 1 | |

Ford Mustang Exhaust, Suspension, Transmission, & More Tech Articles - 5.0 Mustang and Super Fords |

| Jerry's 1969 Ford Mustang Restoration in 2006 | |

1965 Shelby Mustang GT350 Clone Project |

| 1967 Ford Mustang Fastback Project Car - Hot Rod Magazine |

|

If you'd prefer to see all of Shadowfast's technical details in ebook form, Dark Horse: The Official Shadowfast Supercar Technical Reference is now available for any Amazon Kindle or Kindle app.

All text above not explicitly authored by others copyright © 2004-2015 by J.R. Mooneyham. All rights reserved.